DOH & HPD Lead Violation Removal NYC-- Professional Solutions for Conformity

DOH & HPD Lead Violation Removal NYC-- Professional Solutions for Conformity

Blog Article

Important Tools and Strategies for Efficient Lead Violation Cleaning

Dealing with lead offenses efficiently demands a detailed approach that blends the right tools with tactical methods. Concurrently, the use of specialized cleanup devices, such as HEPA vacuum cleaners and lead-specific cleaning agents, is vital for thorough contaminant elimination. Efficient control techniques, consisting of plastic sheet and adverse air pressure systems, are important to protect against the spread of dangerous products.

Personal Safety Equipment

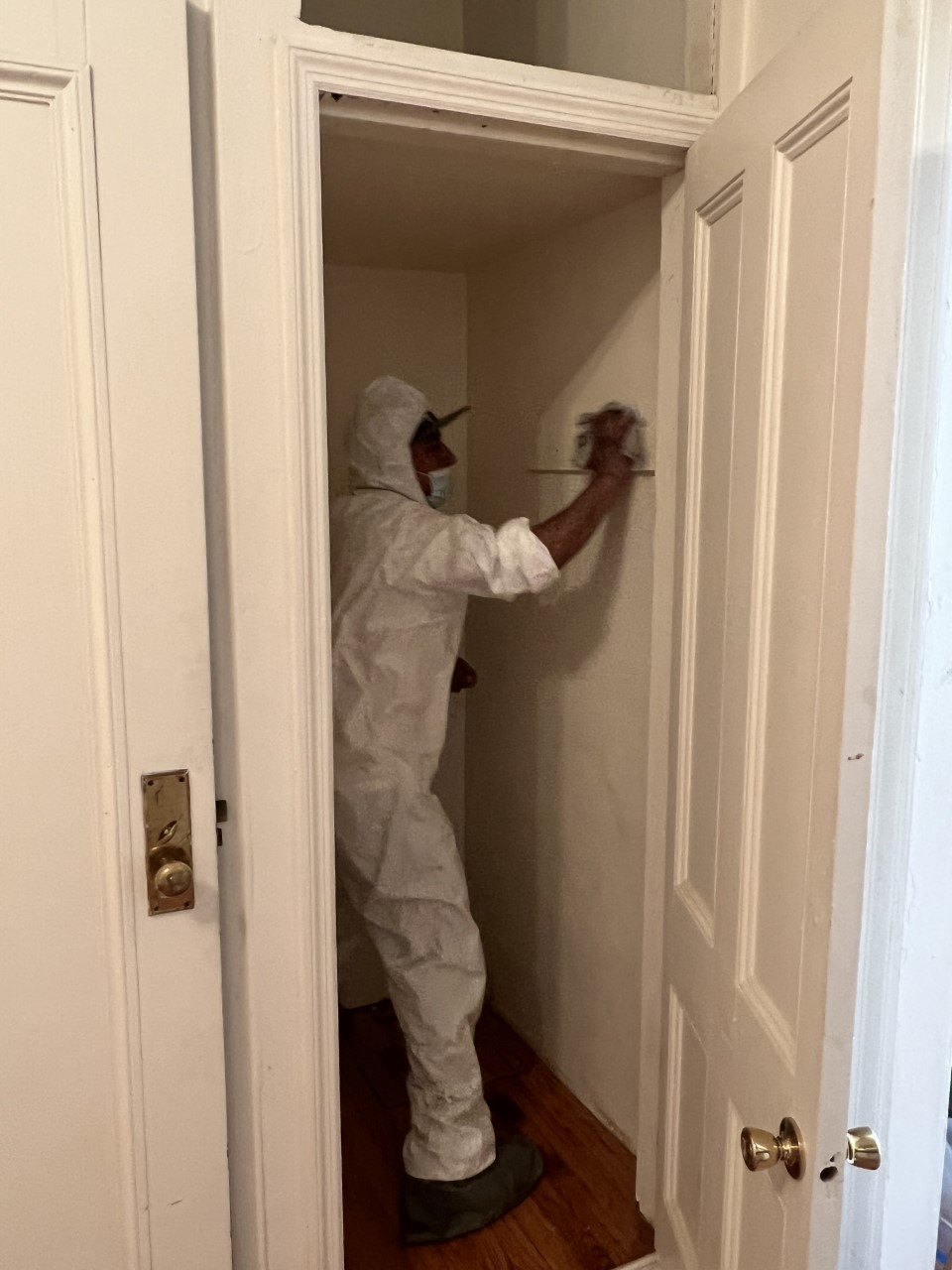

Individual safety tools (PPE) is a vital element in the reliable management of lead contamination cleaning. The crucial PPE for lead clean-up includes respirators, safety clothing, handwear covers, and eye protection.

Respirators, particularly those furnished with HEPA filters, are vital for filtering system airborne lead particles, preventing breathing. Correct fit and seal checks are vital to ensure their performance. Safety clothes, including coveralls and non reusable matches, stops lead dust from adhering to employees' garments, decreasing the risk of second contamination. Handwear covers, usually made from nitrile or latex, secure the skin from direct contact with lead, while safety goggles or full-face shields secure the eyes from dirt and particles.

Additionally, strenuous training on the correct use and upkeep of PPE is necessary. Employees need to be informed on wearing and doffing procedures to stay clear of contamination. Normal inspections and replacements of PPE elements are essential to maintain their safety capabilities, guaranteeing a risk-free and compliant cleanup operation.

Specialized Cleaning Equipment

One more crucial tool is the wet/dry vacuum cleaner, which can properly tidy up both dirt and fluid contaminants. These vacuums usually come with HEPA filters to supply an added layer of safety. Wet cleans or tack towels are also important for surface cleansing; they are specifically made to record and hold lead fragments, reducing the danger of spreading contamination.

For even more persistent down payments, specialized lead-removal cleansing representatives are required. These representatives are developed to damage down lead particles, making them much easier to remove. Scrub brushes with tough bristles can aid in this process, specifically on harsh surfaces where lead dirt has a tendency to stick more strongly.

In addition, encapsulants are used to secure lead-contaminated surface areas, preventing the release of lead dust. These specialized paints and coverings are made to comply with different substratums, supplying a long-term remedy for lead containment.

Reliable Containment Techniques

Reliable containment methods are essential in reducing the spread of lead contamination throughout cleanup activities. Applying durable containment approaches makes sure that lead bits do not move to unaffected locations, consequently protecting both workers and the environment. One main approach is making use of plastic sheeting to seal contaminated areas. Durable polyethylene barriers can be mounted from floor to ceiling to produce a controlled workspace, substantially minimizing the danger of airborne lead dirt dispersal.

To improve containment, encapsulants can be used to surfaces that are not being gotten rid of or disrupted. These specialized coatings bind lead dirt, decreasing its schedule for resuspension. Furthermore, all employees need to wear proper Personal Safety Equipment (PPE), including respirators and non reusable fits, to protect against contamination spread.

Safe Disposal Practices

Making sure safe disposal methods is a crucial part in the management of lead contamination clean-up. Proper disposal reduces the threat of lead re-entering the atmosphere and jeopardizing public health and wellness. The initial step is to determine and set apart lead-contaminated waste from various other materials. Safe control using durable, watertight containers is important to stop splilling during transport.

Transporting lead waste requires adherence to stringent guidelines. Utilizing qualified unsafe waste carriers ensures that the products are dealt with properly. Paperwork, consisting of materializes outlining the kind and amount of waste, must go along with deliveries to track the my response waste from the website of beginning to its final disposal destination.

Designated harmful waste disposal facilities are geared up to manage lead-contaminated materials safely. These facilities frequently employ advanced methods such as stablizing, solidification, or chemical therapy to counteract the lead prior to disposal. Landfilling in specialized, lined areas that protect against leachate from infecting groundwater is a common practice for last disposal.

Routine training for personnel associated with lead waste disposal is essential to preserve security requirements and protect against unintentional exposure. By sticking to these methods, companies can considerably decrease the environmental and wellness impacts linked with lead contamination.

Regulatory Conformity Tips

Complying with regulatory compliance is critical in the effective execution of lead contamination cleanup. Comprehending and complying with federal, state, and local guidelines guarantees not just the security and wellness of people but additionally the legal and monetary well-being of advice the cleaning organization. The Epa (EPA) establishes strict standards, such as the Lead Restoration, Repair Work, and Paint (RRP) Rule, which mandates correct certification and training for specialists handling lead-based tasks.

Conformity starts with a comprehensive evaluation browse this site of relevant laws and policies. Organizations should remain upgraded on any kind of legal changes, which can be helped with with routine training sessions and registering for sector updates. Documentation is another vital compliance element; preserving in-depth documents of all tasks, consisting of examination records, staff member training logs, and disposal shows up, is essential.

Moreover, engaging with certified lead examiners or risk assessors ensures that lead hazards are correctly identified and mitigated. Companies have to apply the usage of Individual Protective Devices (PPE) and guarantee that safety protocols are purely adhered to. Last but not least, clear communication with stakeholders, including employees, customers, and regulative bodies, will foster a culture of conformity and responsibility, eventually contributing to a more secure and a lot more effective lead clean-up process.

Conclusion

Effective lead offense cleanup requires the assimilation of specialized tools and calculated techniques to guarantee security and efficiency. Personal protective devices (PPE) safeguards employees from direct exposure, while safe disposal practices and strict adherence to regulatory compliance are crucial for responsibly managing harmful waste.

Report this page